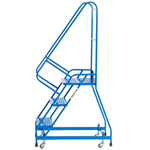

Mobile Safety Steps

Mobile safety steps are essential for accessing high items in warehouses, retail units, schools, and libraries, offering a safer alternative to traditional ladders. These wheeled steps are designed to remain stable with features like locking mechanisms and rubber-capped feet. Available in various styles, from two-tread steps for quick access to larger platform steps for more frequent use, they ensure safety and convenience in narrow aisles and busy environments. For assistance in choosing the right mobile safety steps for your needs, contact our technical sales team at 0808 278 2771.

Mobile safety steps on wheels, perfect for your warehouse

When you need to get to items that are out of reach, a set of safety steps fit for purpose are essential for your business.

Not only do mobile steps make life easier, they also provide a much safer method of gaining height than their wobblier colleagues, the long ladder.

Safety steps, are, in their most basic form, a set of step ladders but mounted on wheels. This makes moving them around your workplace safe and easy.

Another major difference between safety steps and the average step ladder is that safety steps do not fold. They are designed to be a solid structure, based in a permanent location. Although, they're not too great for popping into your vehicle, we'll leave that to the ladders, they do provide an ideal solution for access to items placed up high within a warehouse, retail unit, school or library.

Mobile safety steps are available in a wide range of styles.

If you're simply after a little step-up, something that you and your staff can hop up onto quickly, a set of safety steps with two treads would work a treat. Although the lower height steps are manufactured with hand rails, some do not feature handles. But they're also fine to use for those small jobs, especially if you're not intending to move anything too heavy or bulky which may make you overbalance.

Working around a busy warehouse can be fraught with hazards, so good quality equipment is available for use at all times. Narrow aisles between racking and shelving can mean that steps may be accidentally knocked by other workers, or by electronic equipment such as forklift trucks. Many businesses do not have the luxury of extra wide aisles, therefore a set of mobile safety steps which can nestle horizontally alongside shelves and racks are just the ticket.

Straight ladders such as telescopic ladders or extension ladders, (they're the type commonly used as loft ladders) that are not securely grounded could be unintentionally dislodged, causing not only injury to anyone up the ladder at the time, but also to bystanders who may be injured by falling ladders. Not to mention, potentially expensive damage to stock.

So, it's with this in mind that we look at the finer lineaments of the safety step.

You may be wondering, how do mobile safety steps stay put if they're on wheels?

Well, the wheels are restricted from movement when in use thanks to some cleverly designed wheel locking solutions. The simplest way in which the safety steps remain stable is when just two of the legs have wheels. The other two legs have ordinary feet, often capped with rubber ends to ensure they don't slip.

So, how do you move a set of steps which have only two wheels? They're specially designed to move in one of two ways. One way to move them is to lift the non-wheeled feet with the favourably placed handles, which have been specifically added for your convenience. You can then effortlessly wheel them along, in the manner of a two-wheeled wheelbarrow.

Another variety of warehouse steps with wheels on just two of the four legs, is described as a pull along step. So, unlike those we just mentioned, instead of lifting and pushing the steps, the tilt and pull steps do, as their name suggests. You tilt them towards you, and the wheels on the front of the steps then come into contact with the floor. The back, non-wheeled legs lift off the floor, and hey presto, your steps are effortlessly following along behind you.

The most popular type of wheel braking mechanism is the spring-loaded type that is fitted to glide-along safety steps. One of the fabulous features of these type of step is that they are always ready to be moved (providing nobody is standing on them at the time!)

The wheels are housed in a cup (a little like an upside down tea cup!) The cup has anti-slip rubber edging which springs into action as soon as somebody climbs onto the steps.

Mobile safety steps with handrails provide that extra something to hold onto to encourage optimum safety in the workplace.

And these are not the only safety attributes integral to mobile step ladders with handrails. In fact, our entire range of mobile safety steps are available with ribbed rubber treads. These types of stair treads give excellent grip and surety underfoot.

Handrails can be full length, extending above the the work platform all the way down to the floor, or may just commence from mid-tread to the top of perhaps the tool tray. Whichever type of hand rail you prefer, they're all a highly effective method of ensuring safety and stability when ascending and descending the steps.

If you're looking for something that provides a larger platform for you to work from, it may be worth considering platform step ladders. These are generally larger and heavier duty and although they may feature wheels, and are portable, you wouldn't want to be moving them around all day.

But platform steps are ideal if you're continually up and down to the top shelf in one location. The biggest benefit is the access platform. It means you have room to turn around at the top of the ladder and the ability to stand unaided whilst locating your item.

With such a tremendous range of safety steps, swingback step ladders, combination ladders and even scissor lift type equipment available at ESE Direct, sometimes the selection can be overwhelming. If you're still struggling to decide which would best suit your environment, please give our technical sales team a call on 0808 278 2771 and they'll be more than happy to assist you.